Empresa

Somos un socio internacional de la industria del automóvil y un especialista innovador de la construcción ligera de muelles sometidos a altas solicitaciones y productos afines. Como empresa familiar, nuestro nombre es sinónimo de éxito del negocio a largo plazo y sostenible.

The Mubea Way

Cada uno de los siguientes aspectos no hace una filosofía de la empresa por sí mismo– sumándolos se forma la imagen de lo que llamamos «The Mubea Way». Es el resultado de 100 años de historia de la empresa y, a la vez, la base de nuestra empresa.

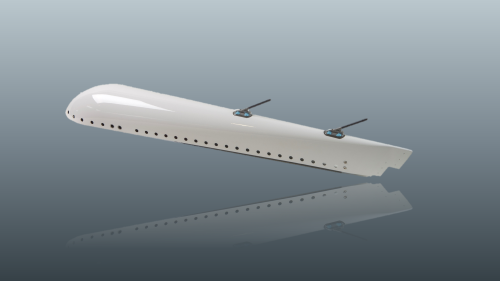

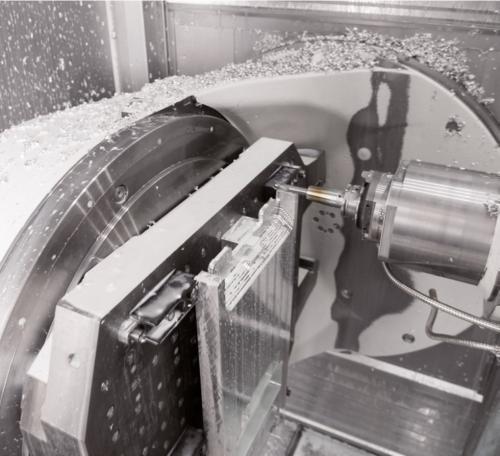

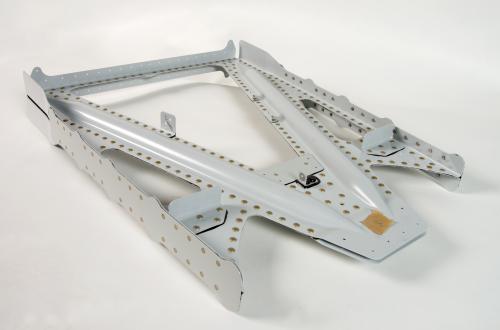

Productos de Mubea

Con productos y tecnologías únicos no hemos establecido como líderes mundiales para nuestros clientes. Desarrollamos soluciones individuales y logramos con ello las mayores reducciones de peso con unos beneficios máximos para los clientes.

CARRERA EN MUBEA

Nuestros empleados son nuestro recurso más preciado. El know-how que trae con usted es nuestro bien más preciado. Su cohesión y motivación son una parte valiosa de nuestra identidad.